Case Study: Solving Rust & Chemical Resistance Challenges for Italix

How Pro-Industrial Pre-Catalyzed Waterbased Epoxy transformed an industrial workspace.

In the world of high-tech industrial manufacturing, your facility needs to perform as efficiently as your machinery. Recently, we had the privilege of partnering with Italix, a forward-thinking company specializing in industrial systems. They presented us with a common but difficult challenge: a facility environment that needed to be chemically resistant, aesthetically sharp, and, most importantly, easy to maintain.

Here is how we utilized Pro-Industrial Pre-Catalyzed Waterbased Epoxy to turn a maintenance headache into a long-term solution.

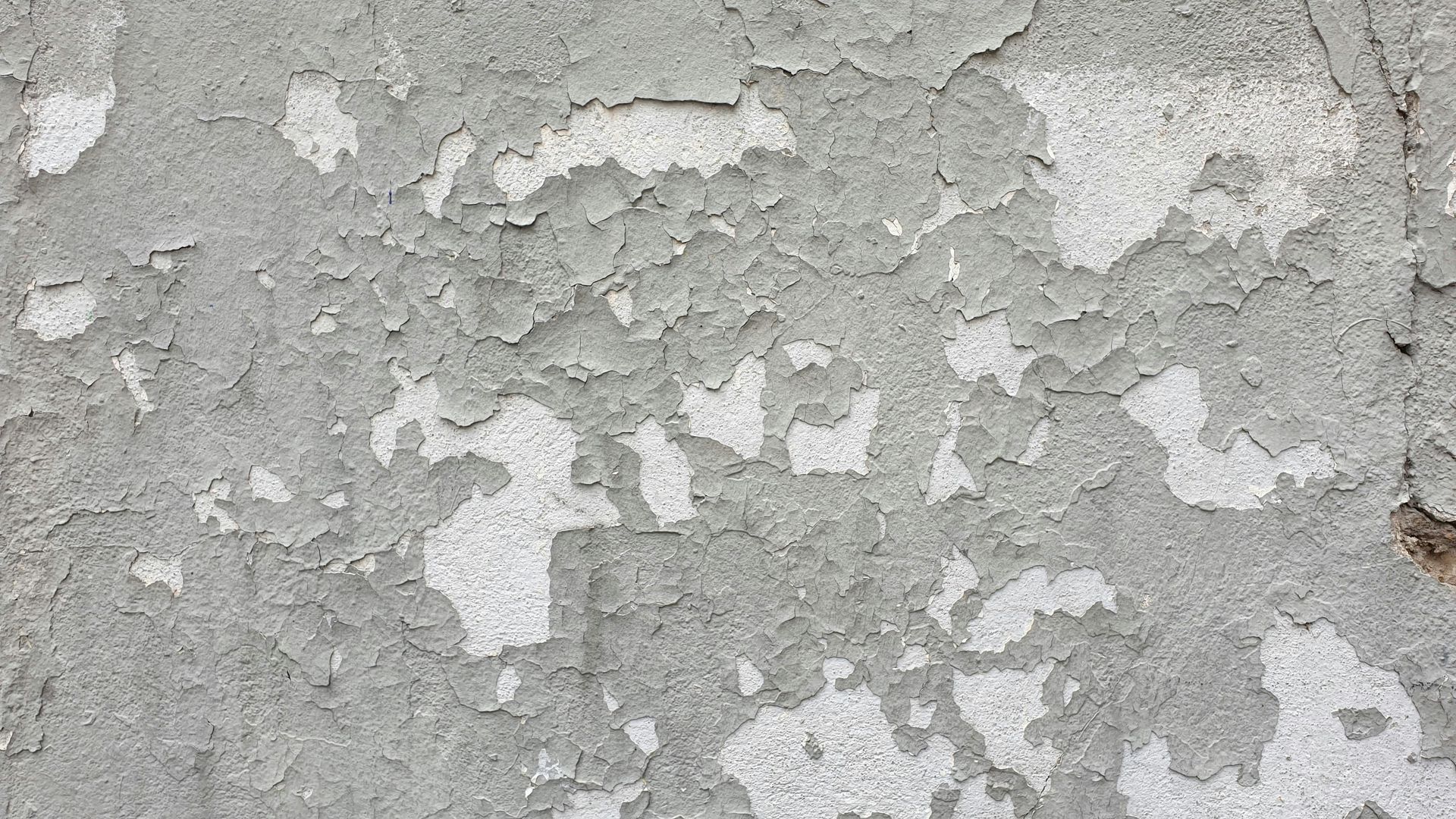

The Challenge: Rust and Resilience

When we inspected the site at Italix, the issues were immediately apparent. The facility walls were suffering from rust buildup—a frequent issue in industrial environments where moisture and chemicals are present.

The client didn't just need a color change; they needed a functional overhaul. Their requirements were strict:

- Chemical Resistance: The coating had to withstand exposure without breaking down.

- Sanitation & Maintenance: The existing rust made the walls look dirty and difficult to clean. They needed a surface where rust and grime could be wiped away effortlessly.

- Adhesion: The substrate required aggressive preparation, including acid etching, to ensure the new coating would stick for the long haul.

The Solution: Pro-Industrial Pre-Catalyzed Waterbased Epoxy

After evaluating the environment, we selected Sherwin-Williams Pro-Industrial Pre-Catalyzed Waterbased Epoxy.

Why this product? In industrial settings, you often have to choose between durability and ease of application. This product offers the best of both worlds. It provides the tough, chemically resistant finish of a traditional epoxy but with the low-VOC and low-odor benefits of a water-based formula. It creates a hard, non-porous finish that stands up to repeated scrubbing and chemical exposure.

The Process: More Than Just Painting

A high-performance coating is only as good as the preparation underneath it.

Our team executed a precise timeline to ensure success:

- Deep Cleaning & Rust Removal: We started by thoroughly removing the existing surface rust. You cannot simply paint over rust; it must be eradicated to prevent bleed-through.

- Acid Etching: To guarantee maximum adhesion, we utilized acid etching. This chemical process opens the "pores" of the surface, allowing the coating to bond physically with the substrate rather than just sitting on top of it.

- Application: We applied the Pro-Industrial coating, ensuring a uniform, sealed finish.

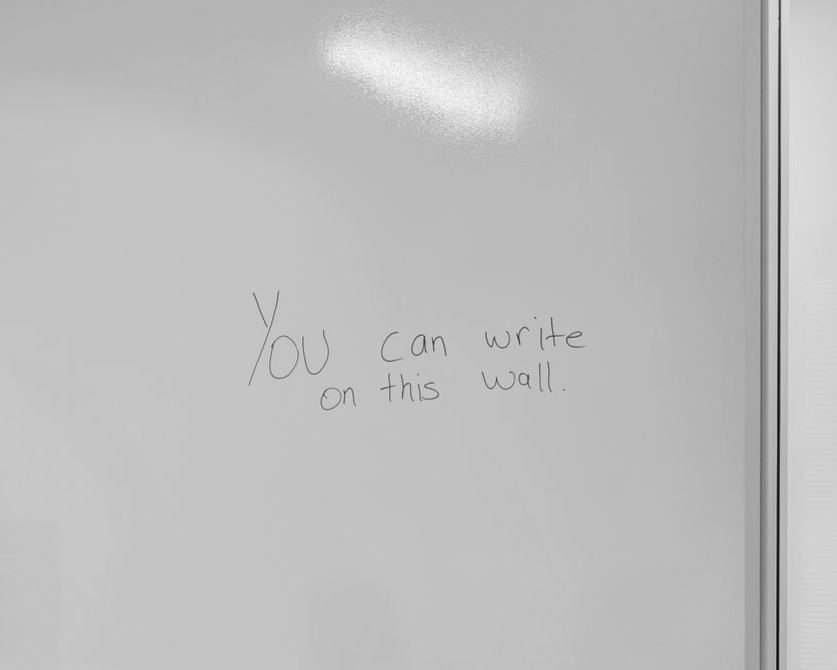

The Result: A Wipe-Down Ready Surface

The difference is night and day. Aesthetically, the facility looks modern, clean, and professional.

However, the real win is functionality. Previously, rust would stain the walls and require abrasive cleaning or repainting to hide. Now, thanks to the chemical resistance of the epoxy shell, any surface rust or residue that settles on the walls sits on top of the coating. The client can simply wipe the rust off the walls without damaging the paint or leaving a stain.

Expert Industrial Surface Solutions

At Commercial Painting Inc., we don't just apply paint; we engineer solutions for your environment. Whether you are dealing with chemical exposure, heavy machinery traffic, or sanitation requirements, we select the right system for the job.

Does your industrial space need a high-performance upgrade? Contact us today for a consultation.

Contact Us

We will get back to you as soon as possible.

Please try again later.